Alstom's brake expertise: Delivering global overhaul and repair solutions from the heart of Spain

Alstom's brake expertise: Delivering global overhaul and repair solutions from the heart of Spain

Begoña Ramos, Managing Director of Alstom Ametsis, explains how a recent acquisition is enhancing Alstom's ability to offer more competitive FlexCare Sustain™ solutions for the repair and overhaul of braking systems – one of the most critical and costly railway services.

Begoña Ramos joined Alstom in 2006 as a Quality and Environmental Technician. Over the years, she gained expertise in rail services and project management, serving as Services Quality Director for the Middle East and Africa, and later as Quality and Continuous Improvement Director for North America. In 2023, following Alstom's acquisition of Ametsis, she became Managing Director of Alstom Ametsis.

Connect with Begoña on LinkedIn!

What are the challenges of brake repairs and overhauls for rail assets?

One of the challenges for the brake business is that because brakes are safety-critical, every repair or overhaul must comply with safety regulations that vary widely from country to country. Some regulations apply more-or-less globally, but in a region such as Europe, regulations may be stricter, for example on main lines or high-speed lines. Metros or tramways that are managed by local authorities vary from place to place.

There are several aspects to compliance, for example, testing equipment. You must first demonstrate that the overhauled equipment complies in laboratory conditions. Then the customer will typically install a prototype, and you spend a year or more further testing the equipment in commercial service before going ahead with the full delivery. So, compliance needs both time and collaboration with customers.

In terms of maintenance, it is also critical to have the right expertise to work on braking systems. In addition, the cost of maintaining brake systems on a train is around 15% of the total cost of train maintenance, mainly due to the cost of components produced by only a few suppliers. Therefore, being competitive in maintenance is also one of the challenges that we have.

How is Alstom positioning itself as a major player in brake maintenance?

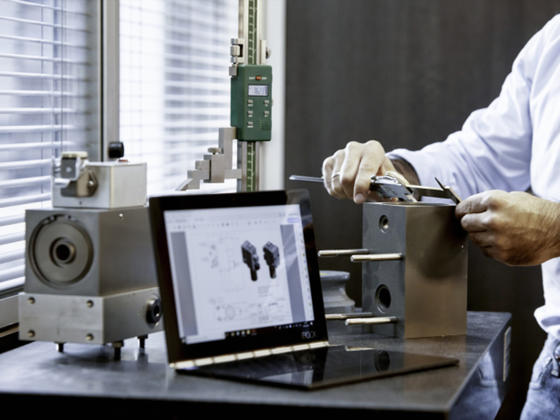

Firstly, we have a Component Services Centre specifically for brakes, where we have consolidated the knowledge of the company and where our brake specialists are based. This is in Madrid, Spain, but the team supports Alstom projects worldwide. In addition, the acquisition of the Spanish company Alstom Ametsis last year brought us further technical expertise on braking systems. From both expertise centres, we provide support and training so that Alstom projects can carry out brake overhauls in-house. We already have in-house projects for brake repair and overhaul ongoing in Kazakhstan, Algeria, and Australia leveraging our global expertise, wheel meeting specific local needs. This means Alstom can be less reliant on other equipment manufacturers for brake components and therefore be more competitive.

What brake overhaul expertise does Alstom Ametsis bring?

Alstom Ametsis can carry out the complete overhaul and repair of braking systems and has a portfolio of overhaul kits for brake equipment. They already had more than 200,000 references for overhaul kits prior to joining Alstom, and the design and development of these kits continues. Alstom Ametsis also designs and develops test benches, so equipment can be tested to make sure that it has been properly repaired and that it matches the train’s parameters. It also produces its own brake components, such as compressors and valves, and is developing other parts. A very important added value for Alstom is the technical expertise of the 38 employees of Alstom Ametsis, so we can provide even more support to different Alstom projects worldwide. With the acquisition also came the suppliers and customers that the company was already working with, which has proven to be very valuable for Alstom.

What is the added value for Alstom's customers?

Our customers now have more options in terms of suppliers, which boosts competitiveness and enables us to respond more rapidly to customer needs. Producing more in-house means we can be more competitive on price than alternative suppliers and deliver cost-effective overhaul kits to customers. Also, we can provide exceptional customer care as we are less dependent on third parties and can respond to our customers straight away, based on our own capabilities. For Alstom Ametsis’ Spanish customers, we will continue to provide the same service as before, which, for smaller customers, is important because they may not be the priority for other large suppliers. Our strategy is to grow to support Alstom projects worldwide, while not forgetting our customers in Spain.