FlexCare Sustain: Rail parts, repairs, and overhauls for safe and reliable fleets

Flexcare sustain at a glance

- Simple and fast parts ordering and delivery

- Reduced inventory with digital warehouse

- 24/7 support through worldwide network of service centres

- For Alstom and other OEM parts and components

- Overhaul solutions for all major subsystems

- Proactive obsolescence management

Maximise the availability and longevity of your rail assets with Alstom’s FlexCare Sustain™ solutions for parts, repairs, overhauls and obsolescence management. We offer flexible contracts from on demand orders to long-term agreements, with committed costs and lead-times. Alstom provides 24/7 customer care through our worldwide network of service and repair centres to sustain the safety and reliability of your fleets for the long run.

StationOne marketplace for sustainable parts supply

StationOne™ is your digital solution for simplifying sustainable online parts sourcing. Our B2B online marketplace provides a platform for operators to purchase parts and components for their fleets, with over 158,000 products from various rail sector vendors, including Alstom. Ordering is simple, with personalised support and real-time information on your order. StationOne offers circular economy solutions, from second-hand to repaired parts and equipment, as well as overstock, allowing you to reduce your carbon footprint.

Worldwide component overhaul expertise

No matter where your fleets are operating, Alstom experts are nearby to help. Our ten component services centres provide specialised support and a customised maintenance plan for all major rolling stock subsystems including power modules and switchgears, traction, bogies, brakes and train control management systems. We bring your components back to their original condition by leveraging technical expertise, engineering capabilities and knowledge on all key components as an original equipment manufacturer.

Proactive obsolescence management

Rolling stock typically have a lifetime of up to 40 years, and it is inevitable that various electronic components and sub-systems will become obsolete over time. We sustain the safety and reliability of fleets with proactive obsolescence management. Alstom has a proven obsolescence management track record with solutions from monitoring to full reverse engineering, or to sustain the technology, to extend service life and reduce the lifecycle costs of your fleet. Our approach includes a thorough root cause analysis, collaborative efforts with suppliers, and a focus on cost-effective management strategies.

FlexCare Sustain™ key figures

Experts in brake system repairs and overhauls

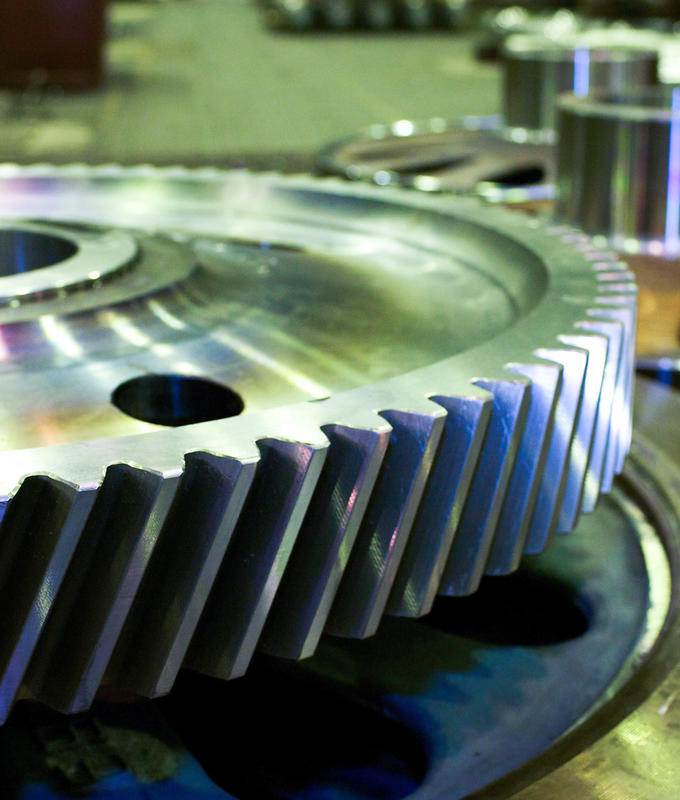

Brakes are a critical subsystem for the overall technical performance of trains. As an original equipment manufacturer, Alstom has expertise in designing, manufacturing and maintaining braking systems, including hydraulic and electro/pneumatic equipment. Our brake component service centres support you with customised maintenance plans to cover your unique needs and bring your braking systems back to their original condition. We also offer engineering, industrialisation, testing and training services for maintenance activities on site.

We are developing our in-house capabilities to supply high-performing brake equipment and provide repairs and overhauls for braking systems to our customers by insourcing through strategic mergers and acquisitions. Over the past few years, Alstom has strengthened its expertise in braking systems with the acquisition of companies such as Ibre, specialised in the development, manufacture and supply of cast iron or steel brake discs; Flertex, specialised in the design and manufacture of brake linings for braking systems; and most recently, Ametsis, the benchmark for design, manufature and maintenance of braking systems.

When you choose Alstom as your maintainer, you get all the engineering and executional support of the vehicle integrator. As an original equipment manufacturer, we integrate our industrial and engineering capabilities into our repair and overhaul services, to ensure high performing subsystems. Our maintenance teams are continuously trained and supported to deliver world class overhaul, repairs and product improvement services. Alstom also provides services for braking systems produced by other original equipment manufacturers.

Alstom has services sites around the world with expertise in braking systems. Our component service centre for brakes in Madrid, Spain, supports customers worldwide on hydraulic and pneumatic systems, including those relying on technology from other manufacturers. We also have sites where we provide brake overhauls, such as in Kazakhstan, where we focus on pneumatic brakes for locomotives, and in Algeria and Sydney where we have hydraulic capabilities. Alstom is currently developing capabilities for pneumatic brake repairs and overhauls at a services site in Chile.