Société du Grand Paris, w porozumieniu z Île-de-France Mobilités, wybiera Alstom jako dostawcę pociągów dla linii 15, 16 i 17 Grand Paris Express

Société du Grand Paris, w porozumieniu z Île-de-France Mobilités, wybiera Alstom jako dostawcę pociągów dla linii 15, 16 i 17 Grand Paris Express

25 SEPTEMBER 2018 - As a result of the negotiated procedures preceded by the tender announced in 2014, the Société du Grand Paris, in consultation with Île-de-France Mobilités, selected the Alstom rolling stock manufacturer to design and deliver trains for metro lines 15, 16 and 17 Grand Paris Express.

The contract, financed entirely by Île-de-France Mobilités, covers an amount of almost EUR 1.3 billion and covers the development and delivery of up to 1,000 wagons (183 trains), which will be used in two versions of trains of different lengths - 3 or 6 wagons.

On July 11, 2018, the board of Île-de-France Mobilités approved the first tranche of EUR 680 million to cover expenses related to the purchase of the first 53 trains for Grand Paris Express. The order for Alstom entails the delivery of 150 wagons (25 trains, 6 train cars) for a total amount of over EUR 280 million [1] .

New, efficient subway trains on steel wheels will reach a speed of 110 km / h in a low-maintenance automatic mode. On the 15th line, 6-car trains will run, and on the 16 and 17 lines - 3-wagon trains. The first trains will leave the factory in 2022, and their commissioning is planned for 2024.

Île-de-France Mobilités will make these trains available to future operators, allowing them to use next-generation materials, based on the latest technological solutions and ensuring a high level of performance. Travel will be both convenient and fast.

As Valérie Pécresse , president of the Île-de-France region and president of Île-de-France Mobilités, said: "Thanks to air conditioning, monitoring, USB sockets and efficient information tools on board, the new Île-de-France Mobilités trains will provide a high level of convenience and security for passengers of the new liniile-de-France metro line, and this is an issue that I always pay attention to when ordering new materials, urban, regional (RER) and metro trains as well as buses and trams. These metro trains will be a symbol of the modernity and dynamism of the leading economic region in Europe. "

"The purchase of trains intended for running on the Grand Paris Express lines is another step towards the implementation of the new metro plan. It is also the effect of orders in the field of civil engineering and opens the way to the first orders for systems that will be part of this infrastructure. This is good news for companies that have seen an increase in orders, as well as mieszkańcówle-de-France residents, for whom the Grand Paris Express is growing every day, "said Thierry Dallard , President of the Société du Grand Paris.

" We are extremely proud of the continued confidence of the Île-de-France Mobilités and the decision of the Société du Grand Paris for this new order to be awarded to us. In particular, we are pleased that through this new project will support implementation of the government's plan, which assumes a double extension of the Paris metro network in the next 15 years " , said Henri Poupart-Lafarge , President and CEO of Alstom.

The new face of public transport

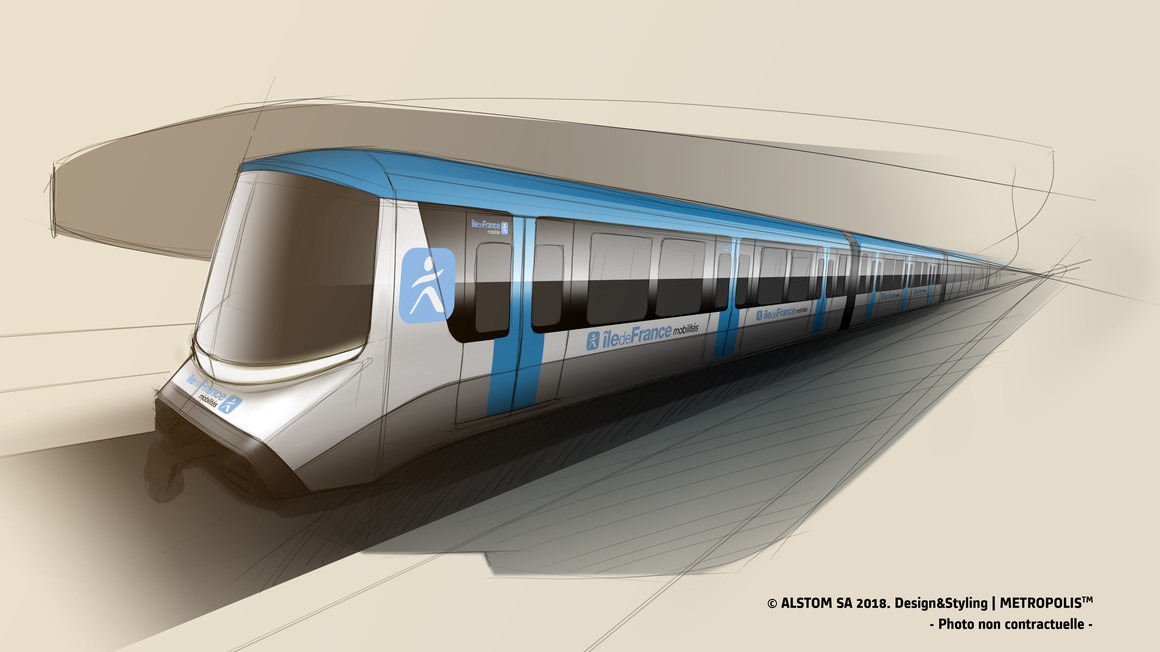

The new subway trains for lines 15, 16 and 17 are open all the way, allowing passengers to travel in a social atmosphere and enjoy a comfortable space. There are three doors on each side, which increases the smoothness of getting on and off, and makes it easier for passengers to move around during the journey. Equipment, especially air-conditioning, lighting and seating, guarantee a high level of comfort. Passengers will also be provided with connectivity thanks to USB sockets, which enable charging the phone. In addition, a wide panoramic windshield will be placed on the rear of the train.

Based on the solutions used in Alstom Metropolis models, improved thanks to the opinions of passengers, new subway trains for lines 15, 16 and 17 guarantee the highest level of availability, reliability and safety. Each train will be able to carry up to 500 passengers in the 3-wagon variant (54 meters) and up to 1000 passengers in the 6-wagon version (108 meters). Maintenance optimization was the key issue. The onboard diagnostic system will provide information on train equipment and overall fleet condition, which will make it easier for maintenance personnel to plan for maintenance maintenance work so that it does not interfere with the timetable. Alstom has also expanded the sequence of maintenance work on new trains, which will allow for a significant reduction of costs throughout their lifetime.

Numerous innovative solutions guarantee the ecological efficiency of new materials, which brings with it a number of benefits. The latest technology developed by Alstom provides optimized energy consumption in traction systems and auxiliary converters. Particular attention has also been paid to the issue of noise, vibration and pollutant emissions. Electric braking up to very low speed and limiting the use of the brake disc will help to minimize particulate emissions from the braking system. In addition, braking energy recovery will play a role in charging batteries and supplying energy to a general electrical circuit. It is also worth mentioning that the train recycling rate is over 96%, and the recovery rate, in accordance with applicable European standards, is over 98%.

A total of 350 Alstom employees will work on this key project in France, including 150 experienced engineers who will endeavor to ensure that it is successfully implemented. Thanks to this project in France, over 1150 new jobs will be created in the local railway sector. In addition, Alstom, as a solidarity-based company, will ensure that a significant part of the work hours planned in France under this contract are reserved for people struggling with particular social or occupational difficulties.

Six Alstom plants in France will design and produce trains. The plant in Petite-Forêt, Valenciennes county, will be responsible for project management, research, development, production, assembly and approval. Five other Alstom plants in France will design and produce components: forklifts in Le Creusot, engines in Ornans, traction systems in Tarbes, on-board electronics and remote maintenance systems in Villeurbanne, and a project in Saint Ouen.

[1] The order will be posted in the third quarter of the current tax year at the latest.